Closed-circuit cooling towers can be categorized based on their cooling principles into counterflow, parallel flow, crossflow, wastewater, hybrid, and integrated heat exchange stations. Each has a distinct structural design and operating mechanism.

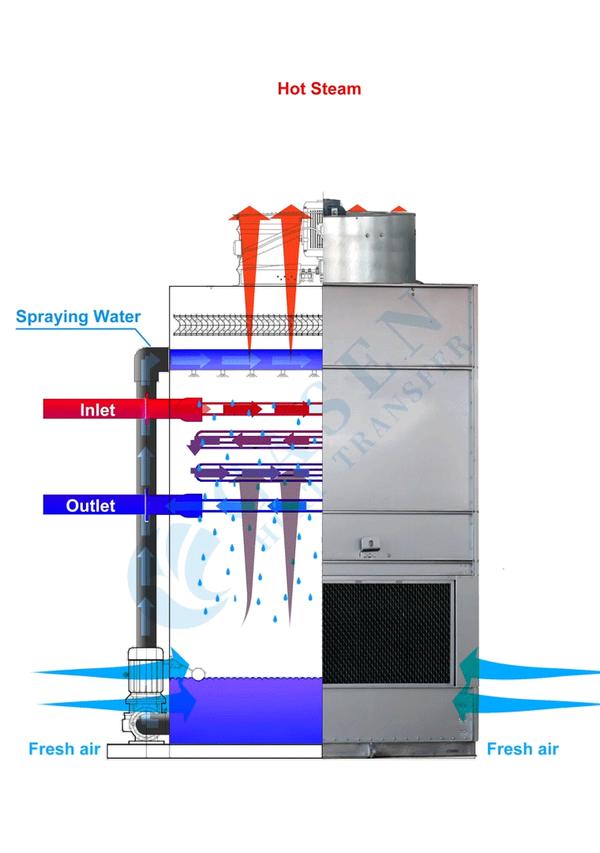

1️⃣ Counterflow Closed-Circuit Cooling Tower

🔹 Working Principle:

- The working fluid circulates within the coil inside the tower.

- Heat from the working fluid transfers through the coil walls to the sprayed water outside.

- A fan draws in air from the bottom, moving upward in the opposite direction to the water flow.

- Some water evaporates, absorbing heat and forming warm humid air, which is discharged at the top.

- The remaining water collects at the bottom and is recirculated by a pump.

📌 Key Feature: Efficient counterflow heat exchange maximizes cooling performance.

2️⃣ Parallel Flow Closed-Circuit Cooling Tower

🔹 Working Principle:

- The working fluid (water, oil, or other liquids) flows inside the coil, while spray water surrounds the coil externally.

- Heat transfers from the fluid to the water and air, forming saturated hot steam.

- A fan expels the heat into the atmosphere, while the water droplets are collected and recirculated.

- Spray water is cooled through PVC heat exchange panels before being reused.

- The airflow and water flow move in the same direction (parallel flow), reducing scaling on the coil walls.

📌 Best For: High-temperature fluids (~60°C) or large cooling differentials (e.g., 60°C → 35°C).

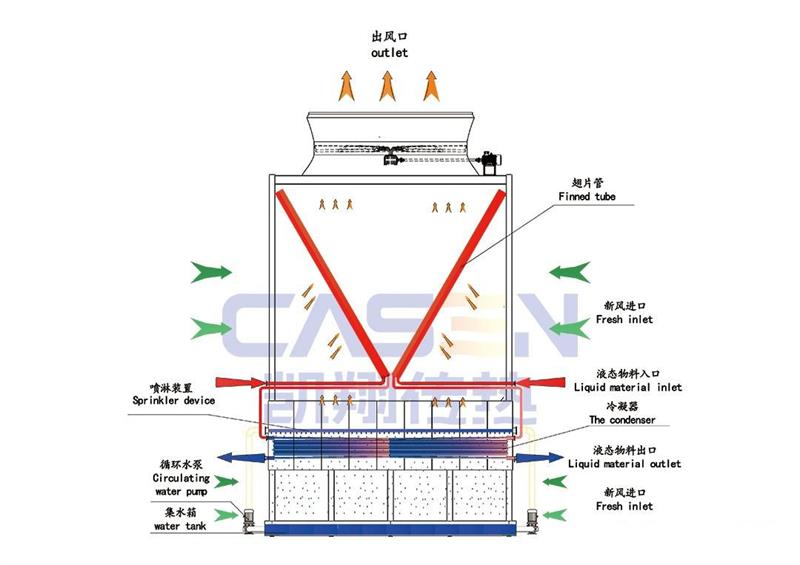

3️⃣ Hybrid Closed-Circuit Cooling Tower

🔹 Working Principle:

- The working fluid first passes through a finned coil unit located above the demister and below the fan.

- The first cooling stage: Sensible heat is dissipated from the finned coil to the air, reducing the thermal load on the main coil section.

- The second cooling stage: Spray water flows over the main coil, allowing latent and sensible heat exchange.

- The remaining heat is expelled through the fan, while un-evaporated water collects and recirculates.

📌 Key Feature: Pre-cooling via the finned coil reduces evaporation losses and increases efficiency.

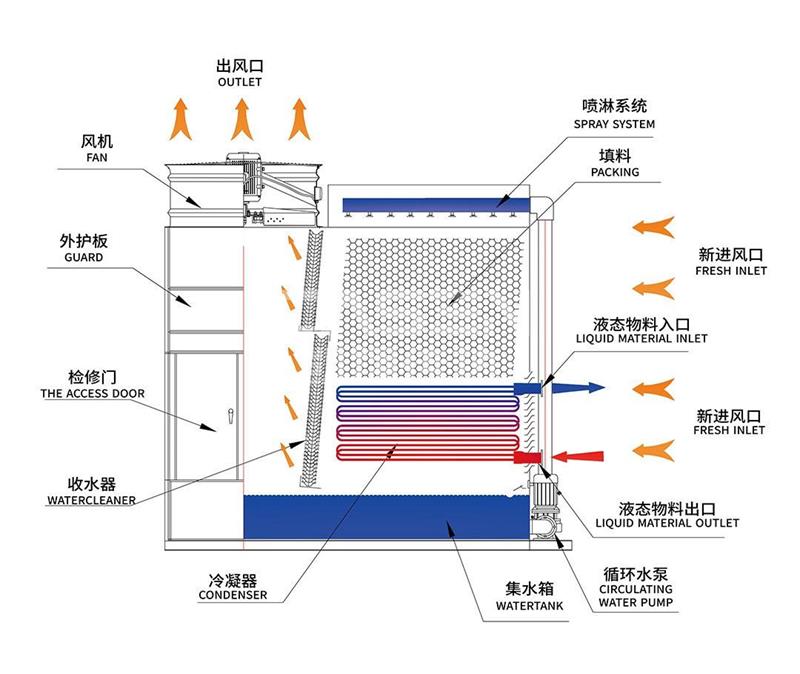

4️⃣ Crossflow Closed-Circuit Cooling Tower

🔹 Working Principle:

- The working fluid flows inside the coil, while spray water surrounds it externally.

- Heat is transferred from the fluid to the spray water and air, forming hot vapor.

- The fan expels the heat, while a collection system prevents water loss.

- The air enters laterally (from the sides) and moves horizontally across the sprayed water, promoting efficient heat exchange.

- PVC heat exchange panels further reduce water temperature before recirculation.

📌 Best For: Applications with strict noise requirements and moderate temperature differentials (ΔT = 4-15°C), such as air conditioning and industrial processes.

5️⃣ Integrated Dry-Wet Hybrid Heat Exchange Station

🔹 Working Principle:

- A typical integrated hybrid cooling system consists of an air-cooling tower and an evaporative cooling tower connected in series.

- Stage 1 (Dry Cooling):

- Hot process water first enters the air-cooled section, where ambient air cools the water via finned tubes.

- Stage 2 (Wet Cooling):

- The semi-cooled water then enters the evaporative section, where it undergoes further cooling via sprayed water and evaporative heat exchange.

- Metallic heat exchangers (such as stainless steel tubes or aluminum fins) improve heat transfer efficiency.

📌 Key Feature: Combines dry and wet cooling for enhanced efficiency and reduced water consumption.

6️⃣ Wastewater Closed-Circuit Cooling Tower

🔹 Working Principle:

- Specifically designed for industries handling contaminated, viscous, or high-fouling fluids.

- Uses detachable heat exchanger designs (e.g., removable plate-type or cap-style heat exchangers) for easy maintenance.

- Ideal for fluids with high scaling tendencies (thermal resistance > 0.00034 m²·K/W) or where chemical cleaning is ineffective.

📌 Best For: Sewage treatment plants, heavy industry, and process industries handling high-fouling liquids.

🔹 Summary: Choosing the Right Closed-Circuit Cooling Tower

| Cooling Tower Type | Air & Water Flow Direction | Best For | Key Feature |

|---|---|---|---|

| Counterflow | Air upward, water downward | General cooling applications | Maximizes heat exchange efficiency |

| Parallel Flow | Air and water flow in the same direction | High-temperature fluids, large ΔT (60°C → 35°C) | Reduces coil scaling |

| Hybrid | Two-stage cooling with finned coil + spray coil | High-load industrial cooling | Pre-cooling reduces evaporation loss |

| Crossflow | Air horizontal, water vertical | Noise-sensitive areas, HVAC | Quiet operation, moderate cooling loads |

| Integrated Dry-Wet | Series cooling (air + evaporative cooling) | Energy-efficient cooling, low water consumption | Combines dry and wet cooling for efficiency |

| Wastewater Cooling Tower | Custom designs for fouling fluids | Heavy industry, sewage plants | Special anti-scaling design |

Conclusion

✅ Different closed-circuit cooling towers suit different cooling requirements.

✅ Counterflow and crossflow towers are common in HVAC and industrial cooling.

✅ Parallel flow towers are best for high-temperature fluids.

✅ Hybrid and integrated dry-wet towers improve efficiency and water savings.

✅ Wastewater towers are designed for contaminated or high-fouling liquids.

🔹 Choosing the right type depends on factors like temperature differential (ΔT), noise constraints, water quality, and operational efficiency.

👉 Now you know how different closed-circuit cooling towers work! 😊