HonMing developed a dry/wet hybrid evaporative cooling tower. It combines the high efficiency of evaporative heat exchangers with the water-saving benefits of air-cooled heat exchangers. This design allows for multiple uses of kinetic and thermal energy. The heat exchanger is optimized for various production processes and harsh site conditions. Different heat exchange principles are effectively combined for maximum performance.

Suit to:

①Larger fluid temperature range cooling (condensing) .

②Higher required process for outlet temperature, continuity and safety.

③Not allow white fog in the site.

④Water source and space are extremely limited in the site.

⑤Especially in the cold northern area, good effect of dry operation without water in winter.

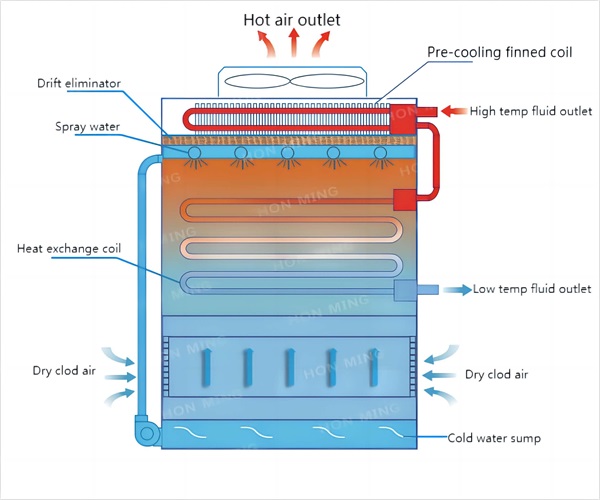

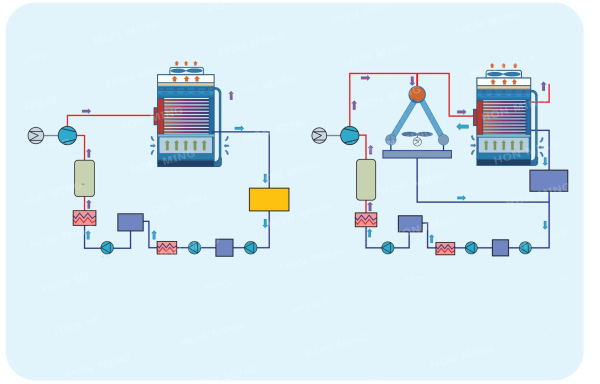

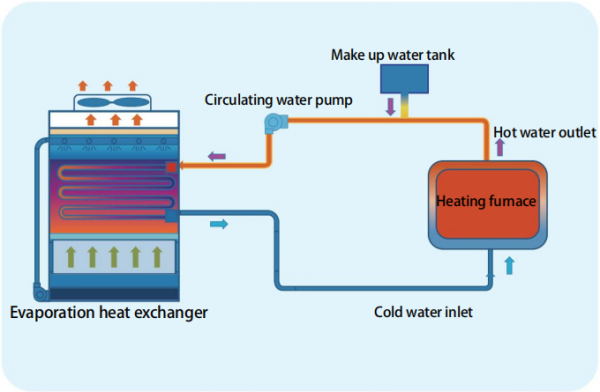

Dry-Wet Combined Evaporative Air Cooler Working Process

Dry/wet hybrid evaporation air cooler application in petrochemical industry: atmospheric and vacuum, catalytic cracking, catalytic reforming, aromatic hydrocarbons, hydrocracking, C4/C5/C9 deep processing, natural gas cooling etc. Coal chemical industry: methanol, ethylene glycol, synthetic ammonia, coal-to-oil, coal-to-gas, coal-to-olefin etc. Steam condensing and industrial circulating water cooling, etc.

Industrial and Commercial Applications

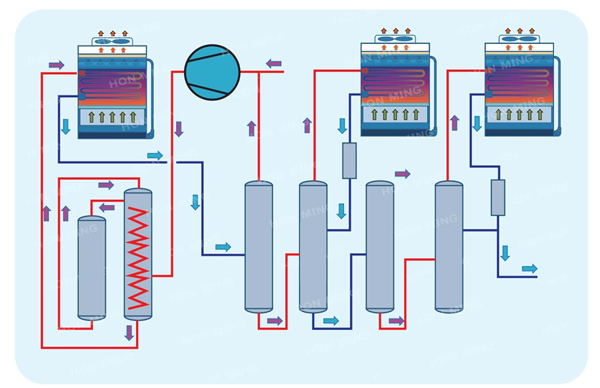

1.Coal Chemical Industry

Dry/wet hybrid evaporation condenser application: Methanol, methylal, ethanol, ethylene glycol, dimethyl ether, butyl octanol,synthetic ammonia, coal-to-oil, coal-to-gas, coal to olefins, coal to aromatics etc. equipment in coal gasification, compression, purification, synthesis, conversion, methanation, distillation and other processes.

Process Diagram

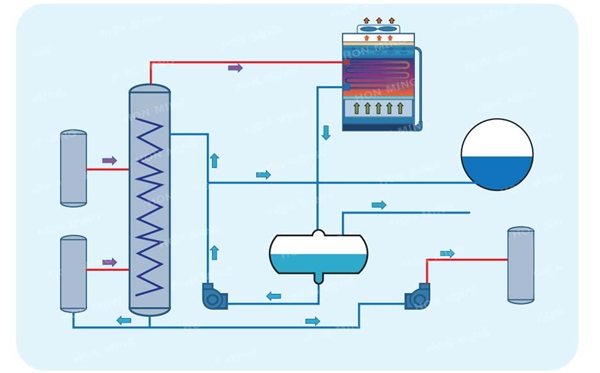

2.Petrochemical Industry

Evaporation condenser application in the petrochemical industry: Normal pressure and vacuum, catalytic cracking, catalytic reforming, aromatic hydrocarbons, hydrocracking,olefins, hydrorefining, gas separation, PX, PTA, MTBE, MTO, MTP , MTA, EO/EG sulfur recovery, C4/C5/ C9 deep processing, natural gas cooling, etc.

Process Diagram

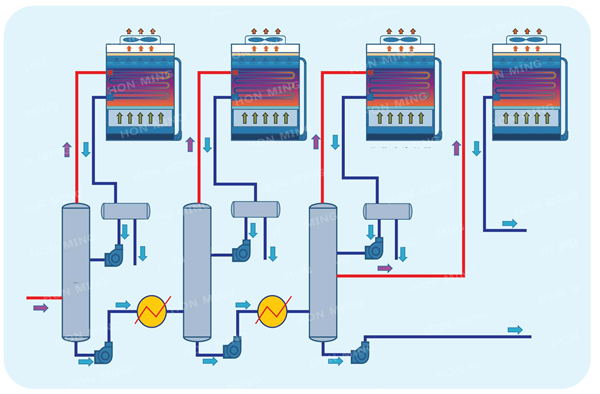

3.Electric Power Industry

Evaporation condenser application: steam condenser for steam turbine exhaust,steam turbine’s cat claw, main steam valve, intermediate valve, water pump base, water pump bearing, fan bearing, generator, motor, etc. Oil cooler of the transformer, etc.

Process Diagram

4.Metallurgy Industry

In the metallurgy industry, evaporation heat exchanger are mainly used for closed-circuit cooling of the blast furnace and hot air furnaces in iron factory,soft water cooling of continuous casting mold and oxygen lance in steel factory, steel rolling factory, blast furnace power plant, casting electric furnace, magnetic material smelting etc.

Process Diagram

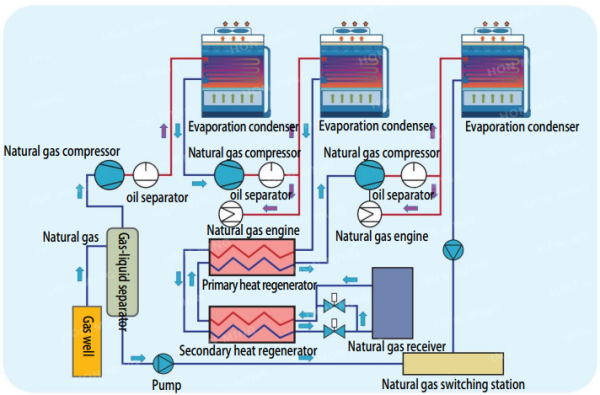

5.Natural Gas Industry

Evaporation condenser used in lubricating oil and multi-stage compression cooler of gas supercharger cooling.

Process Diagram

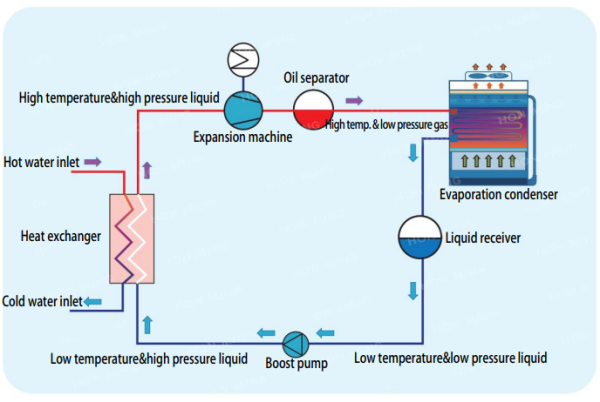

6.Waste Heat Power Generation Industry

Evaporation condenser used in exhaust steam condensing of expansion machine.

Process Diagram

Evaporation Heat Exchanger VS Shell and Tube Water Cooled Condenser

The evaporation heat exchanger is replacement condenser system of the traditional shell and tube water-cooled condenser, open type cooling tower and circulating water pump. It is a new type of energy-saving and water-saving&high-efficiency condensing cooling equipment that integrates water cooling and air cooling, heat transfer and fluid transfer processes. Features: high efficiency heat transfer, low investment,low operating cost,compact structure, small floor space, easy installation and maintenance, low maintenance cost, stable and reliable operation etc.