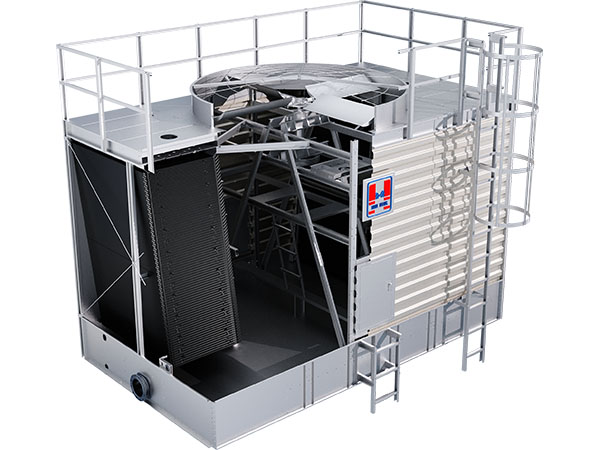

This open cross-flow cooling tower is designed to handle a wide range of water flow rates, from 93 m³/h to 1360 m³/h, making it versatile for various industrial and commercial applications. Its cross-flow design ensures efficient heat exchange by allowing the water to flow horizontally while air moves vertically through the tower, resulting in improved cooling performance. Ideal for both small-scale operations and large facilities, this cooling tower provides reliable and energy-efficient cooling solutions, contributing to enhanced system performance and operational cost savings.

What is the price of a cooling tower?

HonMing cooling tower prices from manufacturer: Open cross-flow cooling towers with a capacity of 93t-1360t are used for chiller cooling, process equipment, and data centers, etc. Price range: $2,950 – $35,000 per unit (minimum order quantity: 1 unit).

HonMing is a professional cooling tower manufacturer, if you want to start your project or plan a cooling solution. Please contact us!

If you want other materials besides FRP such as 304 stainless steel or steel casing, we can also customize the material, please contact us now!

Details of MK-E Series Cooling Tower

Fan Power System

- TEFC motor designed specifically for cooling towers.

- IP55 protection and F-grade insulation for durability.

- High-quality, heavy-load V-belt drive for reliable performance.

- Optional: Gearbox or Direct drive system for flexibility.

High-Efficiency Heat Exchange Filling

- Three-in-one design: drift eliminator, louver, and filling.

- Made of high-quality PVC B1 anti-flame material.

- Oxygen index > 32% for safety compliance.

- Features high-efficiency diversion lines and hanging installation.

High-Efficiency Axial Fan

- Adjustable inclined angle for stable air volume and high efficiency.

- Anti-corrosion material ensures long service life.

- Tailored to different noise requirements by selecting specific fans.

Water Distribution System

- Gravity water distribution with a large diameter and no moving parts.

- Flexible connection methods for ease of installation.

- Optional: Internal pipe system for economic applications.

- Optional: Hot water basin cover to avoid contamination.

- Designed for easy maintenance, reducing water pollution.

Structure Frame

- Made of Zinc/Mg plates with higher durability than industry standards.

- Free Mg+ for self-healing when scratched.

- Optional: SS304 material for enhanced corrosion resistance.

- Includes ladder cage and safety handrail for operational safety.

Advantages of This Type Cooling Tower

Continuous & Reliable Operation

- Sturdy Zinc/Mg plate frame structure ensures stability and high standards.

- Large air volume aluminum alloy fan with excellent corrosion resistance.

- Durable FRP cold water basin design with anti-corrosion properties.

- Large diameter gravity-type water distribution system ensures even and blockage-free water flow without moving parts.

Easy Maintenance & Installation

- Safe internal walkway for convenient access inside the cooling tower.

- Maintenance-friendly gravity-type water distribution system design.

- Flexible assembly on-site and easy transportation.

Flexible Applications with More Options

- Various model selections cater to diverse water flow and site dimensions.

- Frame materials include FRP, Zinc/Mg plates, and SS304.

- Optional components: Belt drive, Gearbox drive, Direct drive fan, VFD, and vibration isolators.

Component Features

- TEFC motors with IP55+ rating, offering moisture-proof and heat-resistant properties.

- High-performance axial fans with aluminum alloy wide blades for large air volume and stability.

- Built-in inverted fan for low noise and easy maintenance.

- High-efficiency PVC filling with drift eliminator to enhance performance.

Environmental Friendliness & High Efficiency

- Use of pro-environment sealing materials with low VOC, benefiting both humans and the environment.

- Gravity water distribution system minimizes pump head resistance.

- Drift eliminators conserve water effectively.

- High-performance motors/VFDs deliver energy efficiency.

AI Cooling Tower Software

- Software compliant with CTI standards, developed using aerodynamic, thermodynamic, and fluid dynamic principles.

- Features parameter selection, performance analysis, environmental impact evaluation, and ROI analysis.

- IoT capabilities enable data transfer to PC or mobile apps.

- Digital programming makes the system visible, analyzable, and predictable.

This series excels in reliability, efficiency, flexibility, and eco-friendliness, making it an optimal choice for diverse cooling requirements.

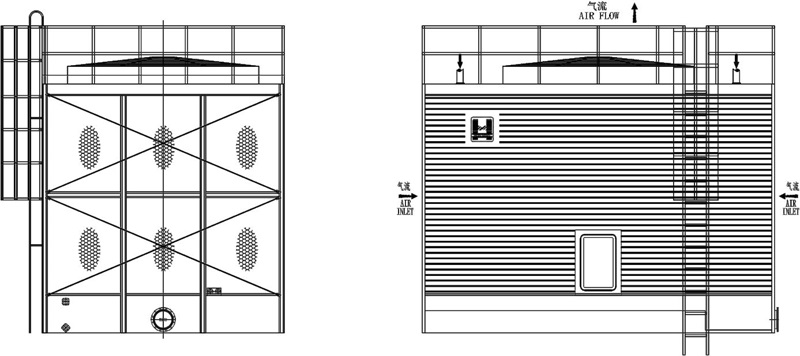

Working Principle and General Process

A cooling tower operates based on the principle of evaporative cooling, where heat is removed from water through the evaporation of a small portion of the water into the surrounding air. Here’s a step-by-step description of the general process:

- Hot Water Inlet: Warm water from an industrial process, HVAC system, or other heat-generating sources is pumped into the cooling tower and distributed over the fill media using spray nozzles or a gravity water distribution system.

- Water Distribution: The water spreads evenly over the fill media, which increases the surface area and allows better contact between the water and the air.

- Airflow: Large axial or centrifugal fans draw ambient air through the cooling tower. In cross-flow designs, air moves horizontally across the falling water, while in counter-flow designs, air moves vertically in the opposite direction to the water flow.

- Evaporation and Heat Exchange: As the air flows through the tower, a small portion of the water evaporates. This evaporation removes heat from the remaining water, reducing its temperature. Simultaneously, heat is also transferred from the water to the air via direct contact.

- Drift Elimination: The air carrying water droplets and vapor passes through drift eliminators, which capture and return most of the water droplets to the cooling system, minimizing water loss.

- Cool Water Collection: The cooled water collects in the basin at the bottom of the tower and is pumped back to the system for reuse in industrial processes or cooling applications.

- Discharge of Warm Air: The warm, humid air is discharged into the atmosphere through the top of the cooling tower.

This process is continuous, allowing the cooling tower to regulate the temperature of the circulating water effectively and maintain system efficiency. Advanced features, such as gravity water distribution systems, high-efficiency fill materials, and AI control software, further optimize performance and reduce energy and water consumption.