Introduction

Product Model and Overview

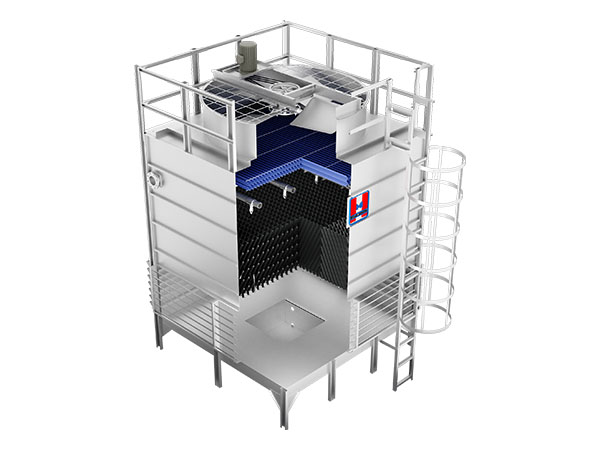

The MR-E Series Open-Type Counterflow Cooling Tower is a new generation product that integrates advanced domestic and international heat exchange technologies. Designed with energy efficiency and environmental protection in mind, this product represents innovation in the cooling tower industry.

If you need or inquire, please contact us immediately!

Product Model Name:

MR-E 075 5020 I/A/D/DS/S-2

Material Options:

- A: FRP Series

- D: All-Steel Series

- D/S: Standard Stainless Steel Series

- S: Full Stainless Steel Series

Product Features and Advantages

- Certifications: CTI, GB/T certified.

Integrated Water Collection Tank:

Standard design features a water outlet on the air intake side (customizable to a bottom outlet at the front end of the air intake side). This design saves on piping systems and simplifies maintenance compared to traditional central cylinder outlets.

Detachable Air Inlet Louver:

Compared to previous metal air inlet louvers, the new design is lighter, detachable, and sand-proof, preventing sand and dust from entering the tower and affecting cooling efficiency. Made from corrosion-resistant PVC with a dual-channel design, it prevents water splashing and reduces algae formation, lowering water treatment requirements and maintenance costs.

Counterflow Tower Fill Material:

Made of vacuum-formed flame-retardant PVC sheets with a B1-level fire resistance. The unique slanted corrugated design offers low airflow resistance, easy placement installation, large heat dissipation area, high thermal performance, and long service life.

Spray System:

Internal piping design saves external space, enhancing the tower’s appearance. Equipped with triple-splash nozzles that are clog-free, maintenance-free, corrosion-resistant, solid spray mode, and easy to install without tools.

Drift Eliminator:

Enhanced ribbed staggered design reduces drift loss better than national standards, ensuring no water drift around the cooling tower. It meets environmental protection requirements, features low operational wind resistance, good rigidity, and is easy to install and maintain.

Motor:

Fully enclosed self-cooling motor designed for cooling towers, suitable for long-term continuous operation in hot and humid conditions. It features high efficiency, low noise, long lifespan, and high reliability. Dual-speed motors or variable frequency drives can be customized upon request.

Gear Reducer:

Advanced industry-standard electrophoresis surface corrosion treatment with hot-dip galvanized main shaft. Compared to traditional paint treatments, its lifespan is increased by 6-8 times.

Fan:

Equipped with silent, airfoil-shaped aluminum alloy fans. The blade tips are welded (unlike riveted joints prone to detachment). Each blade is 420mm wide, and the transition from flat blades to large chord-length blades significantly reduces fan speed while maintaining airflow, thereby lowering noise.

Standard Configuration:

Includes tower-top guardrails, ladder cages, internal baffles for wind and water separation, and movable internal balance ports.

Air Duct:

The external air duct design more effectively expels hot air from the tower, improving thermal performance efficiency by approximately 5% compared to internal ducts.

FRP Panels:

The exterior and bottom middle panels are made of high-quality, high-density, mechanically extruded FRP.

Key Features:

- Double-sided smooth hydrophilic surface with a “lotus effect,” preventing alkaline substances in fiberglass from leaching due to rough surfaces of traditional hand-laid FRP.

- UV-resistant co-extruded resin layer nearly completely filters ultraviolet light.

- FRP is a thermosetting fiberglass-reinforced plastic, resistant to cold brittleness and heat softening, suitable for long-term use from -38°C to 120°C.